Working Time Solutions is now part of Totalmobile

Introducing

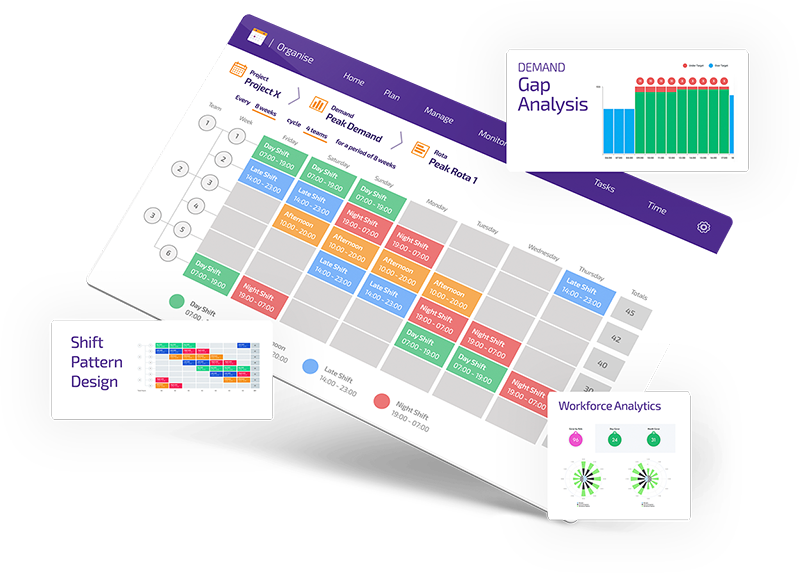

Organise

Shift planning and Rostering solution

A flexible and comprehensive rostering solution supported by expert shift-planning advice that enables organisations to effectively manage their staff to meet both specific and complex rostering requirements.

Shift planning and Rostering solution:

- Better control of operational and staffing costs

- Enhance organisational compliance and risk reduction

- Improve service quality and customer satisfaction

- Support employee well-being

Shift work consultancy:

- Shift pattern design and scenario planning

- Rostering and workforce management best practice

- Diverse industry expertise spanning senior HR and Operations

Current WTS Customers

To find your personal login pages, we have given you links below:

- Managers: Access your software subscription here

- Employees: Access your self-service login here

We can also provide service support on (+44)161 720 5050.

Or alternatively visit our

Knowledge Hub